Melt pump is one of the indispensable equipment for molten polymer melt transportation, pressurization and melt metering. It is widely used in chemical fiber, granulation, plastic film, sheet, plate, profile, pipe, wire and cable, wire drawing, etc. In composite extrusion and other production lines, the materials that can be processed almost cover most polymer materials, such as PE, PP, PVC, ABS, PA, PS, PC, PMMA, etc. The choice of melt pump material has a crucial impact on its performance and service life. This article will discuss in detail the issues related to melt pump materials.

The main materials of melt pumps usually include stainless steel, cast steel, alloy steel, etc. Each of these materials has advantages and disadvantages, and the appropriate material needs to be selected according to the specific use environment and requirements.

Stainless steel is a commonly used material for melt pumps. It has the characteristics of corrosion resistance, high temperature resistance, and easy cleaning. Stainless steel melt pumps are suitable for transporting high-viscosity, high-temperature molten polymer melts and can ensure the purity and stability of the melt. In addition, stainless steel also has good mechanical properties and can withstand high pressure and temperature, ensuring long-term stable operation of the melt pump.

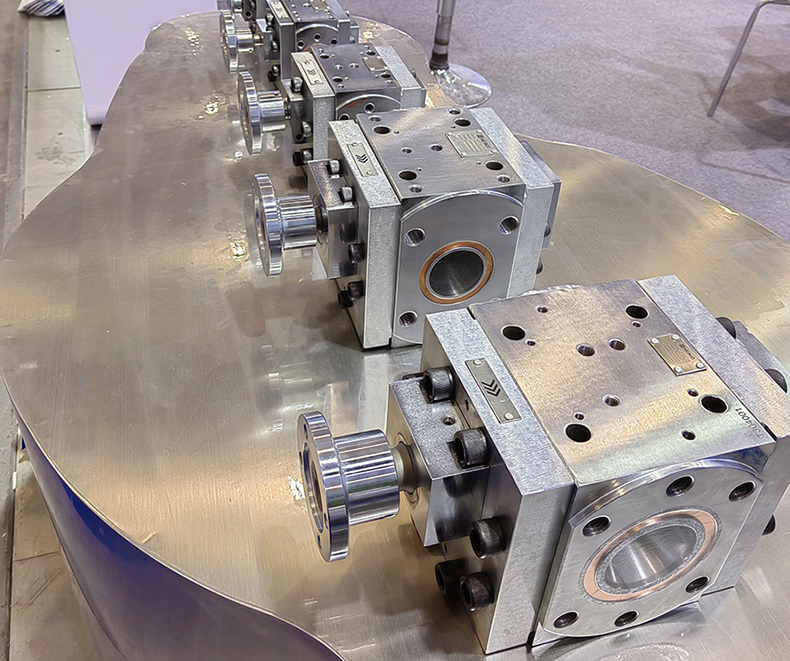

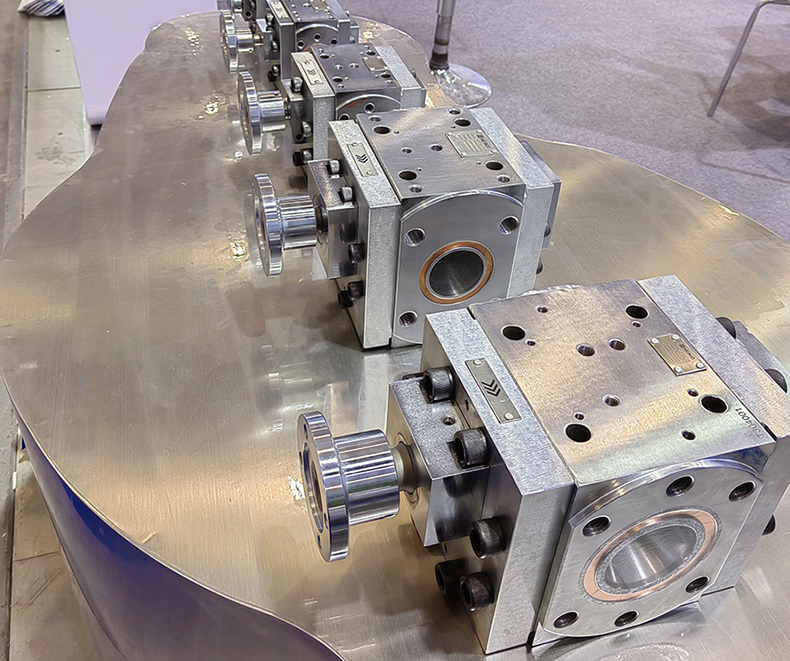

Melt pump

Cast steel is another common melt pump material with high strength and wear resistance. Cast steel melt pumps are suitable for transporting molten polymer melts containing solid particles or highly abrasive, and can withstand large impacts and wear. However, cast steel has poor corrosion resistance and requires careful care and maintenance.

Alloy steel is a melt pump material that combines the advantages of stainless steel and cast steel. It has the characteristics of high strength, high wear resistance, and good corrosion resistance. Alloy steel melt pumps are suitable for transporting molten polymer melts with high viscosity, high temperature and high abrasion, and can meet complex usage environments and requirements.

In addition to the selection of materials, the design and manufacturing process of the melt pump are also important factors affecting its performance and service life. Reasonable design and manufacturing technology can ensure the sealing, stability and durability of the melt pump, and improve the use effect and service life of the melt pump.

In practical applications, it is necessary to select the appropriate melt pump material according to specific production needs and process requirements. At the same time, it is also necessary to pay attention to care and maintenance, and regularly inspect and replace worn parts to ensure the normal operation of the melt pump and extend its service life.

In addition, the selection of melt pump materials also needs to consider factors such as processing performance and cost. Melt pumps made of different materials may require different processes and equipment during processing, so factors such as processing cost and production efficiency need to be comprehensively considered. At the same time, the prices of melt pumps made of different materials also vary greatly, and the appropriate material needs to be selected based on the company's budget and actual needs.

In summary, the choice of melt pump material has a crucial impact on its performance and service life. When selecting the material of the melt pump, it is necessary to comprehensively consider factors such as the use environment, process requirements, processing performance and cost, and select a suitable material to ensure the long-term stable operation of the melt pump and improve production efficiency. At the same time, it is also necessary to pay attention to maintenance and repair, and replace worn parts in time to ensure the normal operation of the melt pump and extend its service life.

In addition, with the continuous advancement of science and technology and the continuous emergence of new materials, the choice of melt pump materials will be more diversified and flexible in the future. For example, the application of new materials such as high-performance engineering plastics and composite materials will bring more possibilities and innovations to the design and manufacturing of melt pumps. Therefore, when selecting melt pump materials, it is also necessary to pay attention to the development trends and application prospects of new materials, and promptly follow up and update the selection to adapt to changing market demands and process requirements.

In short, the selection of melt pump materials is a very critical link in the design and manufacturing of melt pumps. Through reasonable selection of materials, optimization of design and manufacturing processes, and strengthening of care and maintenance, the performance and service life of the melt pump can be guaranteed, and the production efficiency and economic benefits of the enterprise can be improved.