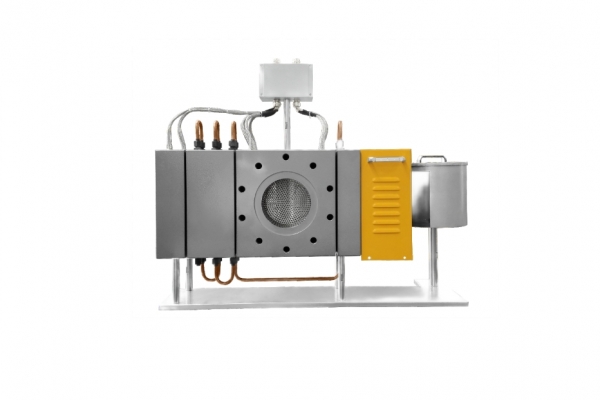

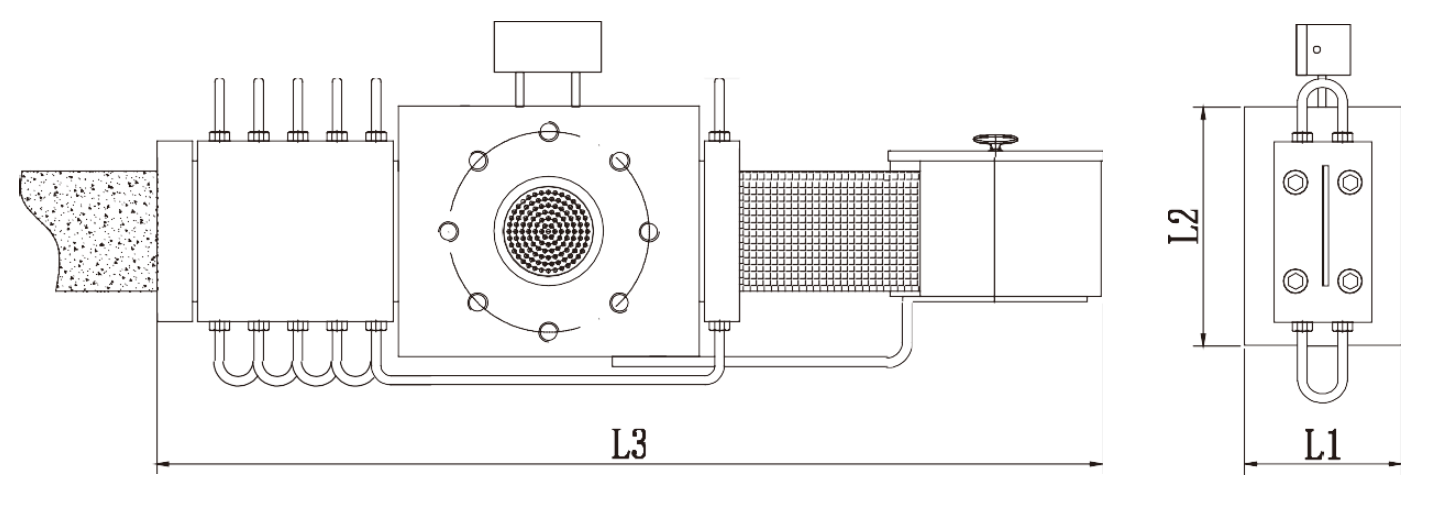

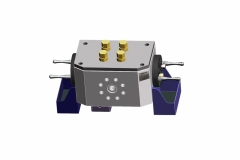

The mesh belt continuous screen changer is an automatic screen changer in the true sense, which uses melt pressure or time to control the action of the screen changer. The distance and speed at which the filter can be moved can be set freely.When the pressure or time reaches the set value, the filter automatically moves evenly, bringing impurities out of the screen changer with the filter. After setting, the screen changer is fully automated, no manual operation is required, the mesh belt moves gently, the distance is small, and the material pressure and material flow do not fluctuate, so as to truly achieve constant pressure production. The mesh belt screen changer adopts water-cooled sealing, no leakage, no wear, and is automatically controlled by the control system for heating and cooling, and the net is flexible. The product is not deformed during the screen change process, and the quality stability is good. It is widely used in the production of high-quality, long-flow or short-range products such as granulation, cast film, sheet, plate, optical fiber, and various wire drawing. It is especially suitable for the production of high-precision products with strict requirements for material pressure fluctuations.

Performance characteristics:

There is no fluctuation in the pressure during the screen changing process, which has no impact on the product quality

Self-sealing, never spillage

Fully automatic network walking, no manual operation is required

It occupies a small space, has a novel structure, and is convenient and simple to install

There is no wear and tear for screen change, and the service life is long

Detachable movable filter block (multi-well plate) for easy service and cleaning

Applications:

Production of high-quality, long-process products such as coating, cast film, sheet, plate, optical fiber, and various chemical fibers.

Production of all kinds of high-quality products with strict pressure requirements

PP, PE, ABS, PMMA and other raw materials granulation production.

PP, PE and other raw materials drawing production line