DETAILS

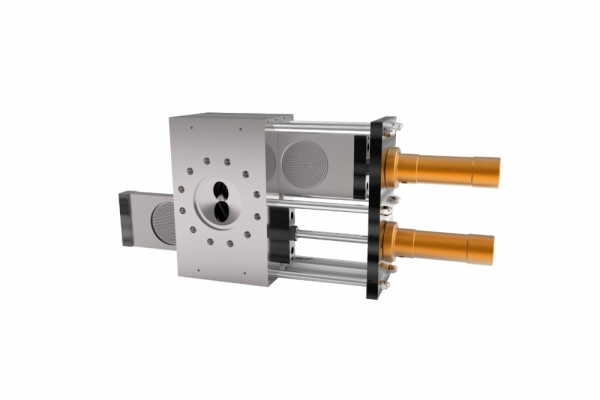

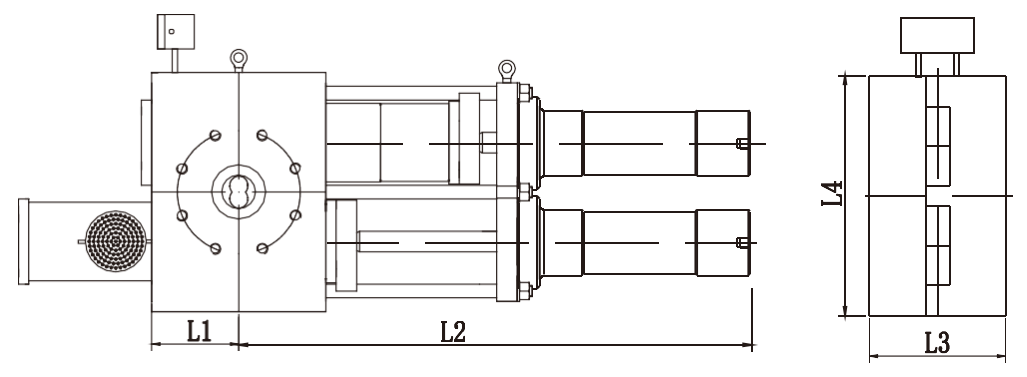

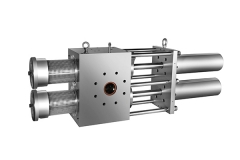

The dual-network application of double-board and double-station fast screen changer can be used at the same time, one network works and one network is replaced when changing the network, without interrupting the material flow, and can achieve non-stop network change. Ensure that the two filter units work at the same time, and its filter area is twice that of a single net. Suitable for all polymer extrusion production requirements. The screen changing process is constantly filtered, which will not cause obvious fluctuations in the production of the extruder and improve the stability of product quality. It can withstand high melt pressures. Reliable sealing structure improves sealing effect.

The double-plate double-station quick screen changer automatically compensates for the sealing gap, which is resistant to high temperature, high pressure, no leakage, and has a large filtration area, which is suitable for high-output equipment. The screen changer does not stop when it does not stop, which can increase output and save energy consumption. It is easy to change the screen and easy to operate and maintain. It is widely used in extrusion production lines such as granulation, pipes, plates, sheets, cast films, etc.