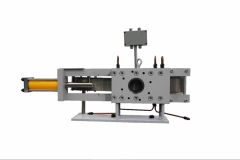

DETAILS

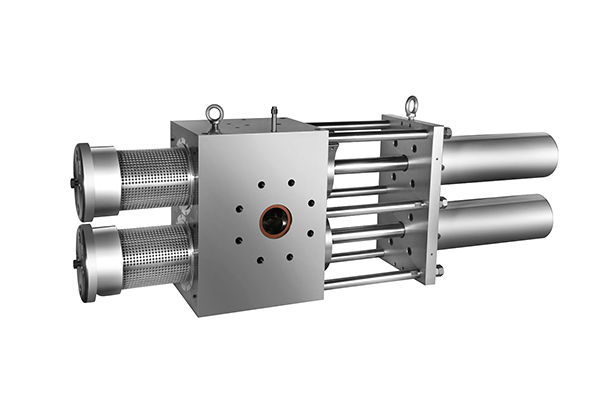

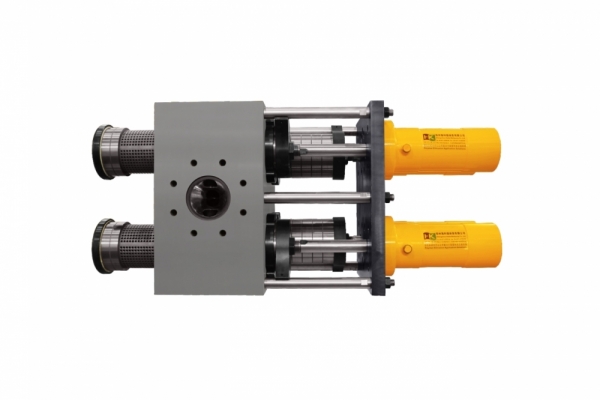

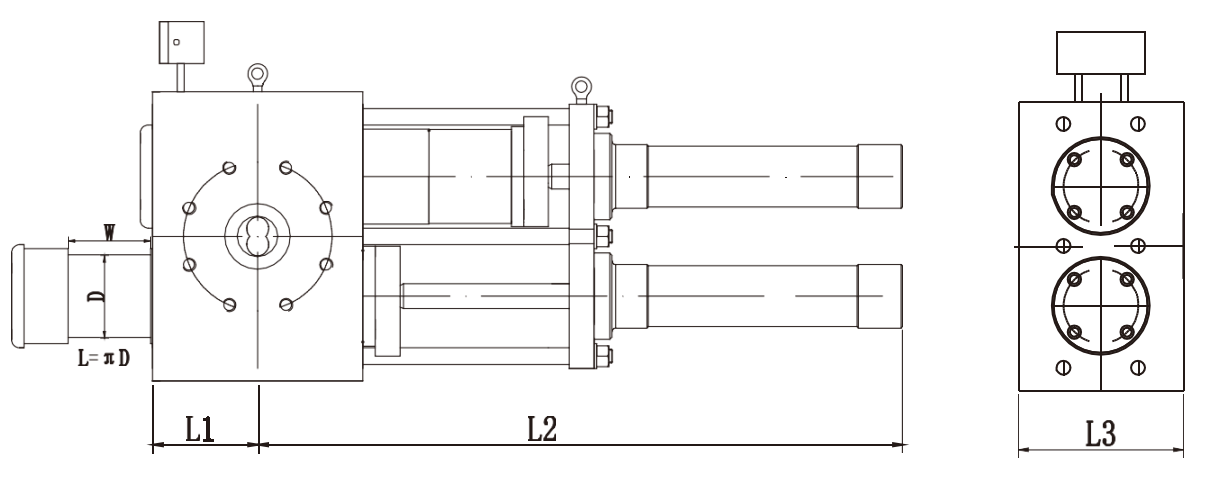

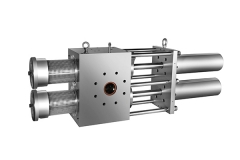

The screen changer is designed as a double-column filter cartridge structure, with a large filtration area, reducing the frequency of screen changing, improving the interval time of screen changing, and can realize non-stop screen changer, and is designed with a material introduction and exhaust device, which can fully exclude the gas in the material, and can completely solve the problem of bubbles when changing the screen, ensure the quality of the product, and improve the stability of the product.

Performance characteristics:

The large filtration area is suitable for extrusion lines with higher output and dirtier materials.

No interruption of material flow, no interruption of products, to achieve non-stop network change operation.

It is suitable for continuous operation of high-capacity, high-efficiency and large-scale extrusion equipment.

The structure design is reasonable and the operation is convenient.

Applications:

The double-column large filter cartridge screen changer is suitable for dirty materials, especially waste with high impurity content, such as PP, PE, PS, PA, AB and other waste granulation conditions, and high filtration precision, large production flow, good stability, high degree of automation on medium and large production lines.