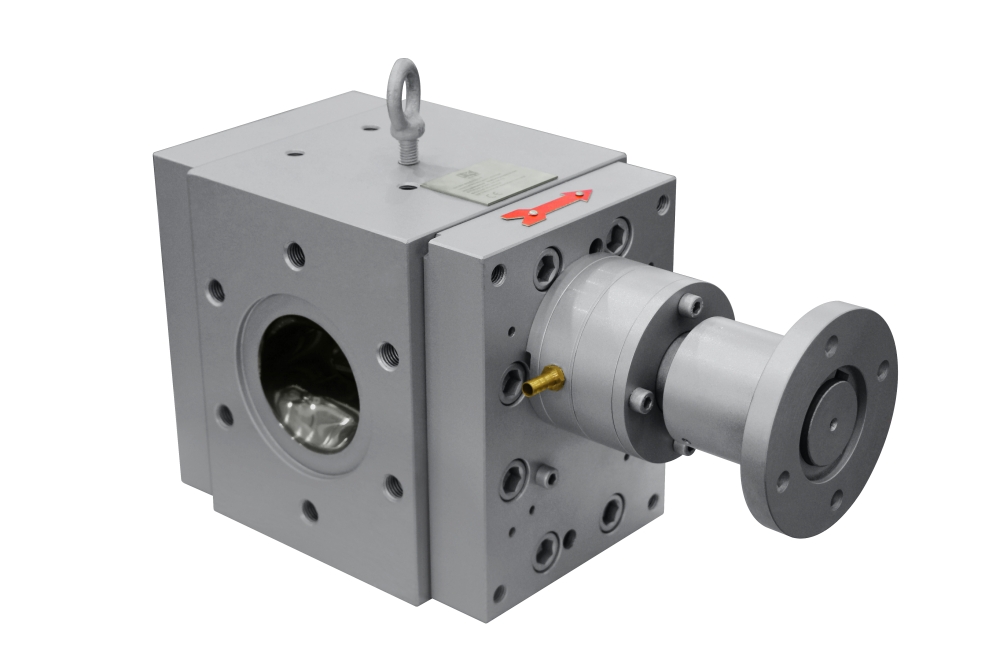

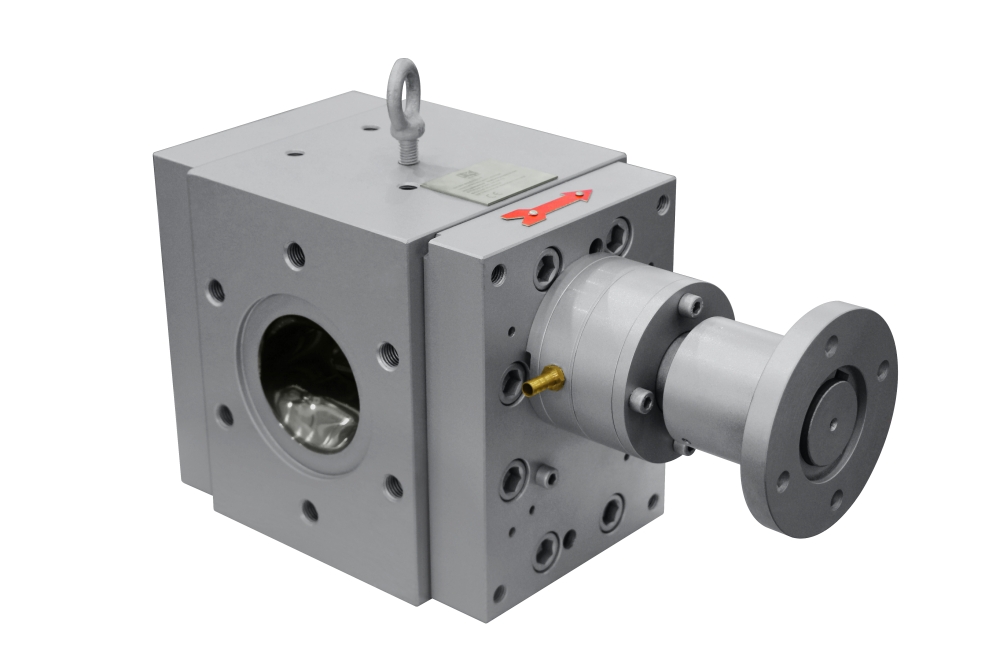

Heiko is a professional melt pump manufacturer in China, providing melt pumps with displacements ranging from 0.1CC-12000CC to meet the needs of users in different rubber and plastic industries.

This article is to analyze and explain several combinations of threaded shaft seals.

1、Threaded shaft seal standard set

Threaded Shaft Seal is the standard seal for Haike MP-M series extruder melt pumps. It is a dynamic seal for high viscosity and suction pressure. It can have a heated or cooled design. The dynamic seal is suitable for high pressures and temperatures. Its field of application is limited by the suction pressure and the viscosity of the pumped medium (at least 10 Pas). If necessary, the viscosity can be increased by additional cooling.

2. Vacuum threaded shaft seal with stuffing box

Vacuum threaded shaft seals are special designs of threaded shaft seals that can also be heated or cooled. The flow to the suction side is stopped by a needle valve, so that the throttled product forms a barrier. This makes it possible to operate the pump on the suction side under vacuum conditions. Due to the dynamic sealing, it is often used in combination with a double locking stuffing box. This combination also prevents air from entering the reactor during shutdown.

3. Vacuum threaded shaft seals with lip seals

Vacuum threaded shaft seals can also be used as static shaft seals together with lip seals. As with the stuffing box packing, the cushioning medium forms the required barrier to reliably prevent air from entering through the shaft seal when the pump is stopped.

Heiko specializes in the manufacture of all types of melt pumps and screen changers.