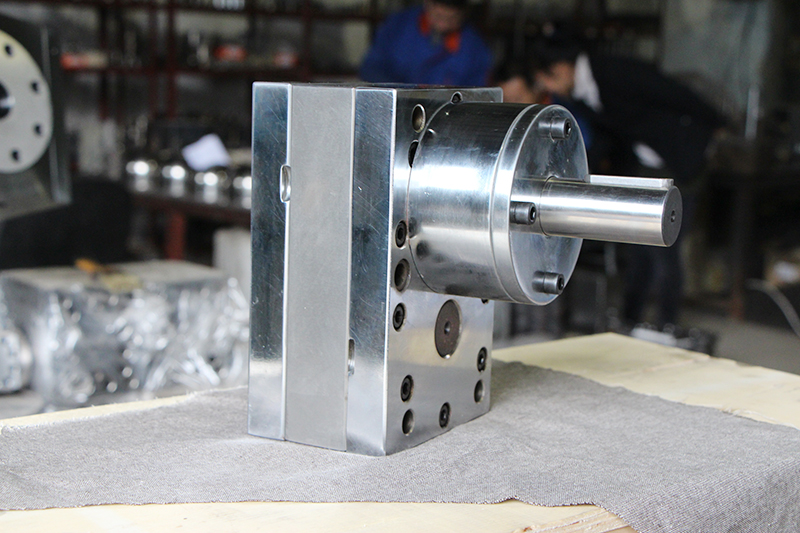

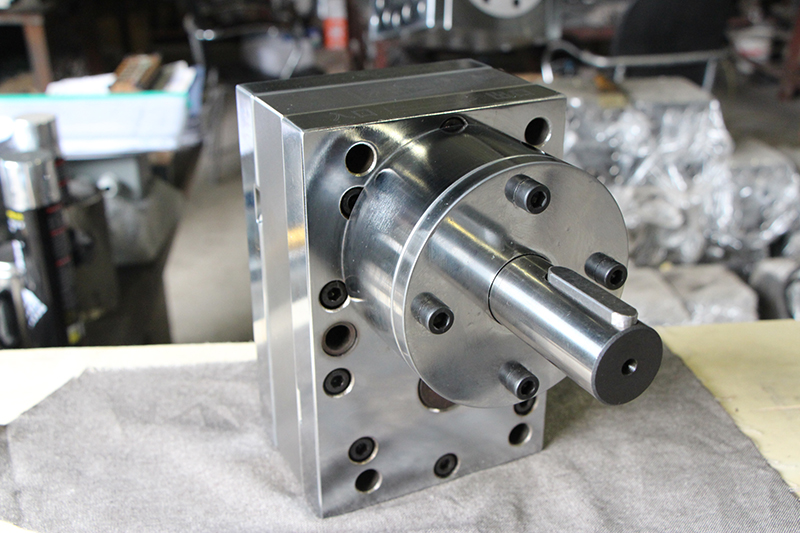

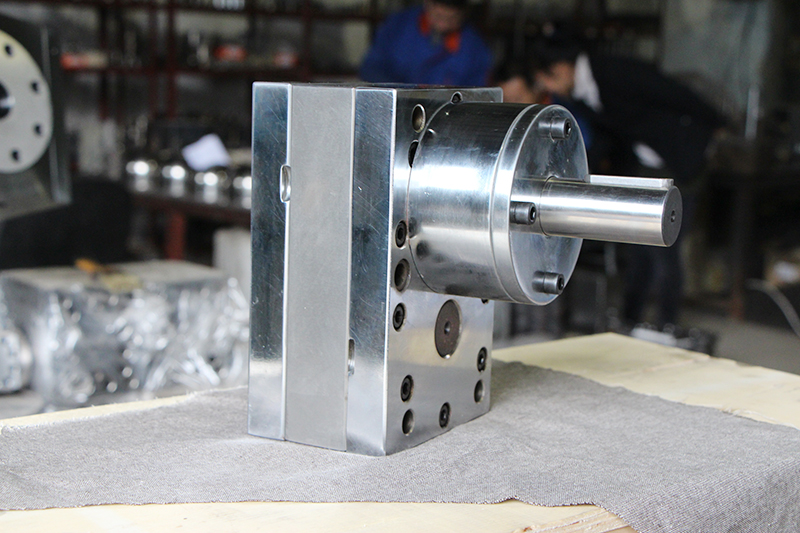

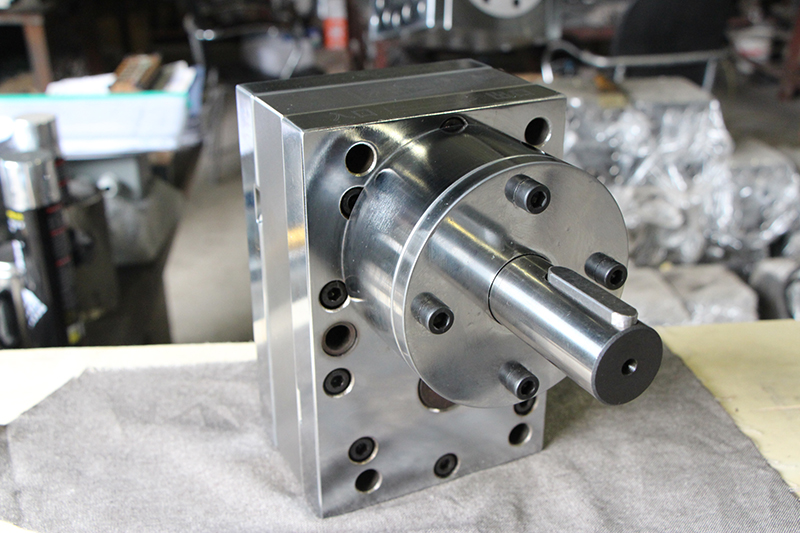

The chemical fiber spinning metering pump, a key component on the spinning machine, is actually composed of a bunch of precision parts! Let me give you a brief overview of its composition structure below!

Base Plate: It fixes the positions of the driving shaft and the driven shaft and is equipped with inlets and outlets, serving as the "gateway" for the spinning melt!

Pump Plate: A closed cavity plate that houses the driving gear and the driven gear, ensuring precise flow control and keeping every drop of melt in check!

Upper Plate: Similar to the base plate, it also fixes the positions of the driving shaft and the driven shaft. It is made of wear-resistant material, capable of withstanding the constant friction from rotation!

Driving Gear: Connects to the motor, transmitting torque to drive the pump, acting like the "heart" of the spinning metering pump!

Driven Gear: Works in conjunction with the driving gear to achieve flow input and output. They are a perfect pair!

Drive Sleeve: Similar to a fuse, it serves both as a seal and as protection for the metering pump, acting as the safety guardian of the spinning metering pump!

Fixing Sleeves, Cover Plates, Gland Plates, Bushings, etc.: Although these parts may seem inconspicuous, they each play an important role, collectively maintaining the stable operation of the spinning metering pump!

So, do you now have a deeper understanding of the composition structure of the chemical fiber spinning metering pump? Next time you see it, don't forget to give it a nod!

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447