First. Technology upgrading and performance improvement

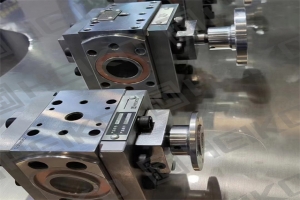

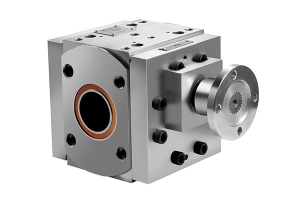

High-pressure: With the increasing pressure requirements of the extrusion process, pipe extrusion melt pumps are developing in the direction of high pressure. This requires the development of new structures that can withstand higher working pressures, such as gear pumps with multiple gears, especially balanced composite gear pumps, to meet the system's demand for high pressure.

Low flow pulsation: flow pulsation will cause pressure pulsation, resulting in system vibration and noise, affecting the quality of extrusion. Therefore, reducing flow pulsation has become an important development trend for pipe extrusion melt pumps. The use of balanced composite gear pumps and other advanced technologies can effectively reduce the flow pulsation, improve the stability of the system and extrusion quality.

Variable displacement technology: the traditional melt pump displacement is not adjustable, limiting its scope of application. With the development of technology, variable displacement melt pump has become one of the research directions. By adjusting the displacement, it can be adapted to different process demands and improve productivity and flexibility.

Second, intelligence and automation

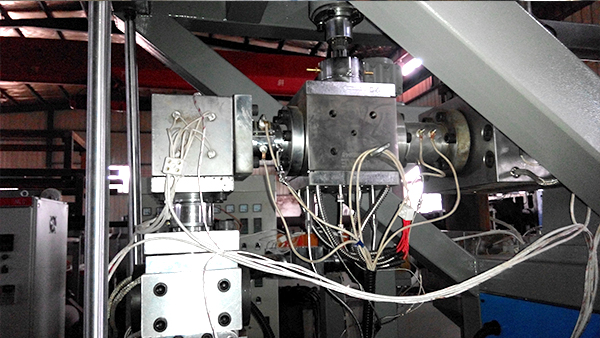

Online monitoring and feedback control: using the melt pump inlet, outlet collected at the pressure, temperature and other information data, you can realize the whole extrusion process of the whole online monitoring and feedback control. This helps to find and solve the problems in the production process in time, and improve the stability of production and product quality.

Intelligent control: with the development of intelligent technology, pipe extrusion melt pump will be more integrated into the intelligent control system. Through the integration of sensors, actuators and controllers and other intelligent equipment, to achieve automated control and optimization of the extrusion process, improve production efficiency and product quality.

Third, to adapt to new materials and new processes

Adapt to a variety of polymer materials: pipe extrusion melt pumps need to adapt to the continuous emergence of new materials, such as high-performance polymers, composite materials, etc.. This requires the pump to have a wider applicability, able to handle different viscosity, fluidity of the melt.

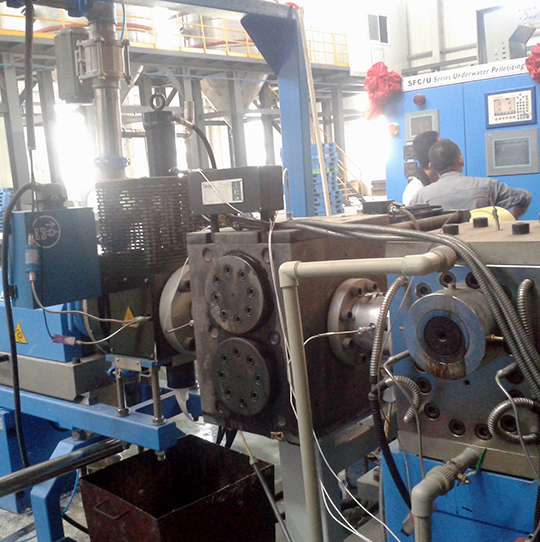

Meet the needs of special processes: with the continuous innovation of extrusion processes, such as co-extrusion, multi-layer composite extrusion, etc., pipe extrusion melt pumps need to meet the needs of these special processes. This may require the development of melt pumps with special structures and functions to adapt to the development of new processes.

Fourth, energy saving and environmental protection and sustainable development

Reduce energy consumption: pipe extrusion melt pumps help to reduce the energy consumption of the entire extrusion system by improving delivery efficiency and reducing back pressure. This is in line with the current trend of energy saving and environmental protection, and helps promote the sustainable development of the plastics processing industry.

Reducing wear and prolonging life: By optimizing the structure and materials of melt pumps, the wear and tear between components is reduced and the service life of the equipment is prolonged. This not only reduces production costs, but also helps reduce waste generation and protect the environment.

Fifth. Market Trends and Competitive Landscape

Market demand growth: with the expanding application of plastic pipes in water supply and drainage, gas, heating and other fields, the market demand for pipe extrusion melt pumps continues to grow. This will promote the continuous innovation and development of melt pump technology.

Intensified competition pattern: With the continuous progress of technology and intensified competition in the market, pipe extrusion melt pump manufacturers need to continuously improve product quality and service level in order to occupy a favorable position in the market.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447