Application Areas of PVC Melt Pumps

Plastic Pipe Production: In the extrusion process of PVC pipes, melt pumps stabilize and pressurize the high-temperature, high-viscosity PVC melt extruded by the extruder, then deliver it steadily to the extruder die. This ensures dimensional accuracy and quality stability of the pipes, enhances production efficiency, and reduces waste rates.

Plastic Film Manufacturing: For the production of PVC films, melt pumps precisely control the flow rate and pressure of the melt, resulting in more uniform film thickness and smoother surfaces. This improves the quality and performance of the films, meeting the requirements of different application areas.

Sheet and Plate Processing: In the extrusion molding of PVC sheets and plates, melt pumps ensure a stable supply of melt, eliminating the influence of extruder screw pulsation. This enhances the dimensional accuracy and appearance quality of the sheets and plates, enabling better performance in subsequent processing and use.

Profile Extrusion: In the production of PVC profiles, such as window and door frames, melt pumps guarantee uniform extrusion of the melt, resulting in more accurate shapes and dimensions of the profiles. This improves the quality and strength of the profiles, meeting the high-performance requirements of industries like construction.

Pellet Production: In the PVC pelleting process, melt pumps accurately meter and stably convey PVC materials that have undergone preliminary mixing and melting. This makes the pelleting process more efficient and stable, producing PVC pellets of uniform quality. These high-quality pellets serve as excellent raw materials for subsequent plastic product processing.

Advantages and Characteristics of PVC Melt Pumps

Optimized Melt Channel Design: PVC melt pumps typically feature specially optimized channel structures that eliminate dead spaces within the channels, minimizing polymer residue. This effectively avoids quality issues caused by material residue, enhancing product purity and quality stability, and ensuring that extruded PVC products meet quality standards.

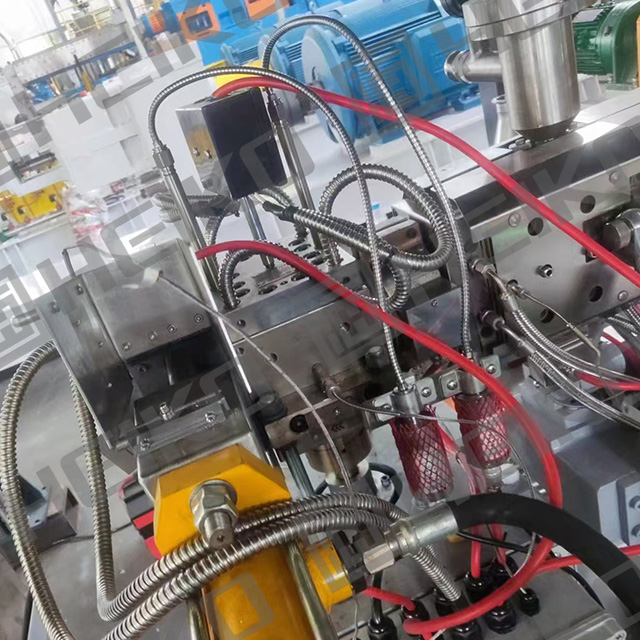

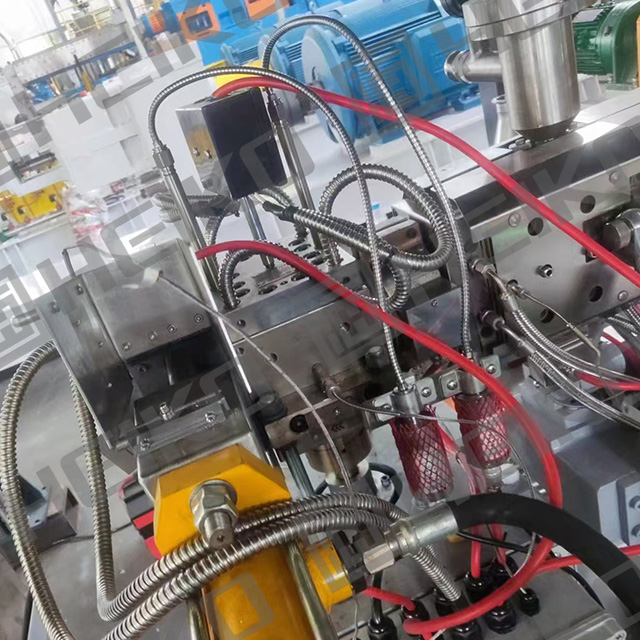

Special Structure Adapted to PVC Thermosensitivity: PVC is a thermosensitive material. The inlet of its melt pump often adopts a flare-shaped channel, with optimized internal channels and gear structures. It also features built-in melt self-lubrication, with lubricating material discharging with the main material. This special structure better adapts to the characteristics of PVC materials, preventing carbonization, decomposition, or scorching due to temperature changes during extrusion, ensuring smooth production and product quality stability.

Improved Gear Parameter Design: With more precise displacement design, the output pressure is more stable, effectively adapting to the requirements of precision extrusion conditions. In the production of PVC products, this stable output pressure aids in precise control of product dimensional accuracy, reducing product defects caused by pressure fluctuations, improving product qualification rates and quality consistency, and meeting high-precision production demands for PVC products.

Nearly Linear Flow Output: As volumetric forced-feed pumps, PVC melt pumps can adjust their output flow by adjusting the pump speed, achieving nearly linear flow output. This feature makes PVC melt pumps easy to control during extrusion, enabling better coordination with upstream and downstream equipment. It allows precise control of melt delivery based on production needs, thus improving automation and production efficiency.

Multiple Installation Methods: Meeting users' individual needs, users can select suitable installation methods based on different production site layouts, equipment configurations, and process flows. This allows the melt pump to better integrate into the entire production system, improving the overall adaptability and flexibility of the equipment.

High-Precision Manufacturing and Excellent Heat Treatment: Adopting high-precision manufacturing processes and excellent heat treatment technologies, the components of melt pumps are more precise and durable. This ensures stable operation of the melt pump under harsh conditions such as high temperature, high pressure, and high viscosity, reducing equipment maintenance and replacement frequencies, and lowering production costs. It also maintains long-term performance stability and reliability, providing robust support for stable production in enterprises.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447