a pioneer in extrusion technology, is excited to unveil its latest innovation: the Double Piston Extrusion Screen Changer. Designed to meet the rigorous demands of modern plastic manufacturing, this advanced screen changer sets a new standard for efficiency, reliability, and performance in the extrusion industry.

The Need for Innovation in Plastic Extrusion

Plastic extrusion is a complex process that requires precision and consistency to ensure high-quality output. Contaminants, pressure fluctuations, and screen clogging are common challenges that can disrupt production, increase downtime, and lead to costly waste. Traditional screen changers often fall short in addressing these issues, leaving manufacturers searching for a more robust solution.

Enter the Double Piston Extrusion Screen Changer – a revolutionary product engineered to overcome these challenges and deliver unparalleled performance.

What is the Double Piston Extrusion Screen Changer?

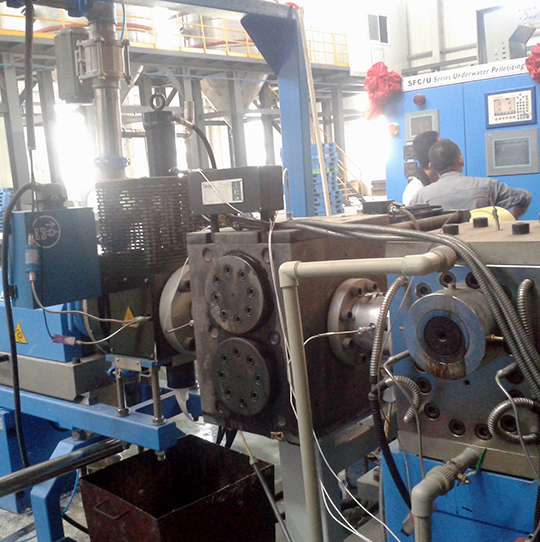

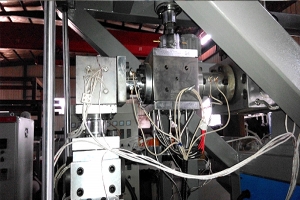

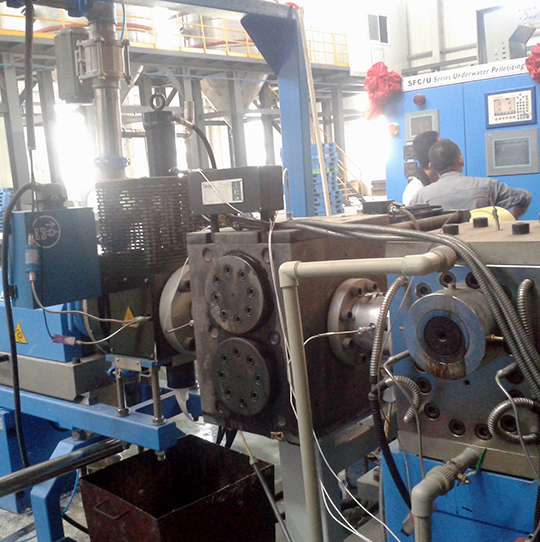

The Double Piston Extrusion Screen Changer is a cutting-edge filtration system designed for continuous operation in plastic extrusion lines. Its unique dual-piston design allows for seamless screen changes without interrupting production, ensuring consistent material flow and superior product quality.

Key Features and Benefits

Dual-Piston Design: The two-piston system enables continuous filtration and automatic screen changes, eliminating downtime and boosting productivity.

Enhanced Filtration Efficiency: Equipped with high-quality filter screens, the device effectively removes contaminants, ensuring cleaner output and reducing waste.

Pressure Stability: The innovative design maintains consistent pressure throughout the extrusion process, preventing defects and improving product uniformity.

Durability and Reliability: Built with premium materials, the Double Piston Extrusion Screen Changer is designed to withstand harsh operating conditions, ensuring long-lasting performance.

User-Friendly Operation: With intuitive controls and easy maintenance, the screen changer simplifies operation and reduces labor costs.

Versatility: Compatible with a wide range of plastics, including PP, PE, PVC, and more, making it ideal for diverse applications.

Why Choose the Double Piston Extrusion Screen Changer?

Maximized Uptime: The continuous operation capability ensures uninterrupted production, significantly reducing downtime.

Improved Product Quality: Consistent filtration and pressure control result in higher-quality end products with fewer defects.

Cost Savings: By minimizing waste and reducing maintenance requirements, the screen changer helps manufacturers lower operational costs.

Sustainability: Efficient filtration reduces material waste, contributing to more sustainable manufacturing practices.

Applications

The Double Piston Extrusion Screen Changer is ideal for a wide range of plastic extrusion applications, including:

Film and sheet production

Pipe and profile extrusion

Cable and wire coating

Blow molding

Recycling processes

The introduction of the Double Piston Extrusion Screen Changer is set to revolutionize the plastic manufacturing industry. By addressing the pain points of traditional screen changers, this innovative solution empowers manufacturers to achieve higher efficiency, better product quality, and greater profitability.

The Double Piston Extrusion Screen Changer is more than just a product – it's a transformative solution for the plastic extrusion industry. Elevate your production process and experience the future of filtration technology with Zhengzhou Heiko Machinery Co., Ltd.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447