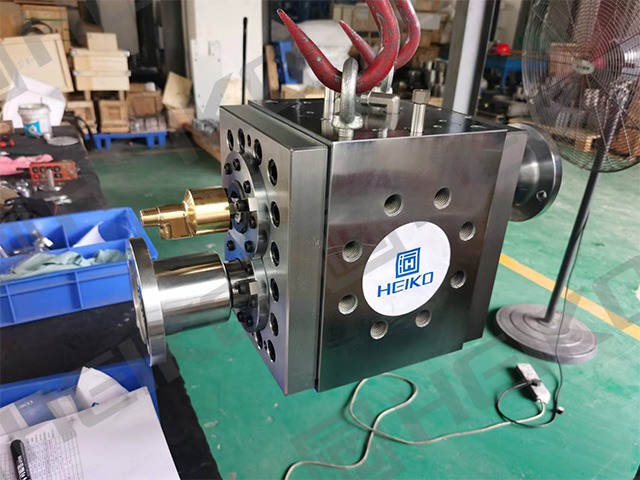

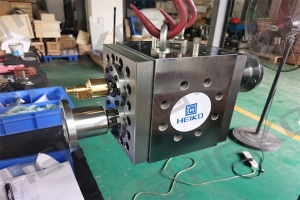

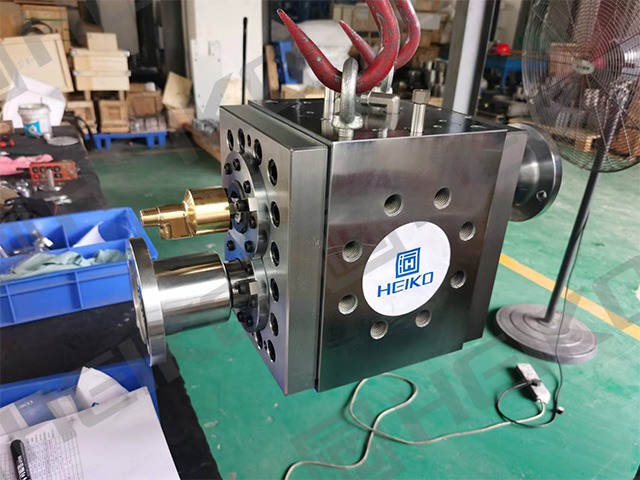

The melt pump for butyl rubber extrusion is designed to handle high-viscosity, high-temperature rubber melts with precision and efficiency. Its structure is engineered to ensure stable pressure, consistent flow, and durability under demanding conditions. Key components include:

Pump Head:

Housing: Made from integrally cast steel or alloy to ensure structural rigidity and sealing performance.

Gear Shafts: Precision-machined straight or helical gears, often crafted from high-wear-resistant alloy steel or tool steel, optimized for efficient torque transmission.

Bearings: Special alloy sliding bearings with built-in lubrication channels for reduced friction and enhanced lifespan.

Seals: Spiral-wound external seals to prevent melt leakage, compatible with high-temperature and high-viscosity materials.

Auxiliary Systems:

Temperature Control: Combines thermal media heating (for maintaining melt fluidity) and shaft-end cooling (to prevent overheating).

Lubrication: Self-lubricating design utilizing the viscosity of the butyl rubber melt itself, minimizing external lubrication requirements.

Drive System:

Motor & Reducer: Typically driven by an electric motor with a gear reducer for adjustable speed control, often integrated with a variable frequency drive (VFD) for precise output regulation.

Performance Characteristics

The pump excels in applications requiring high pressure, stable flow, and resistance to abrasive or corrosive materials. Its performance features include:

Operational Capabilities:

High-Pressure Handling: Capable of generating pressures up to 40 MPa, suitable for precision extrusion of dense rubber profiles.

High-Temperature Resilience: Operates effectively at temperatures up to 350°C, maintaining melt quality and preventing degradation.

Viscosity Range: Manages viscosities up to 40,000 Poise, ensuring smooth flow even with highly viscous butyl rubber compounds.

Precision & Efficiency:

Stable Pressure Output: Minimizes fluctuations in die pressure, resulting in uniform product dimensions and surface finish.

Energy Savings: Reduces extruder load by offloading pressurization tasks, lowering energy consumption by up to 30% compared to traditional systems.

Flow Control: Near-linear flow rate adjustment via speed variation, enabling seamless integration with automated control systems.

Durability & Maintenance:

Wear Resistance: Hardened gear surfaces and optimized tooth profiles extend operational lifespan under abrasive conditions.

Self-Cleaning Design: Streamlined flow channels prevent material stagnation, reducing cleaning downtime and maintenance frequency.

Application-Specific Advantages:

Butyl Rubber Processing: Ideal for extrusion of weatherstrips, seals, and damping components, where dimensional accuracy and material integrity are critical.

Multi-Industry Compatibility: Adaptable to plastics, resins, and elastomers, offering versatility in high-viscosity fluid handling.

The butyl rubber extrusion melt pump's robust construction and advanced thermal management make it indispensable for high-precision rubber manufacturing. Its ability to deliver stable pressure and flow under extreme conditions ensures consistent product quality, while its energy-efficient design aligns with modern production sustainability goals. This pump serves as a critical upgrade for manufacturers seeking to enhance productivity and reduce operational costs in butyl rubber extrusion processes.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447