Thermal degradation of polymer materials can cause a reduction in physical and chemical properties and a change in colour. If it is caused by the melt pump these defects are mainly related to the structural design of the melt pump, one is the pump structure and flow channel stagnation zone problem, and the second is the lubrication method of the melt pump bearing.

In the work of the melt pump import and export pressure difference is very large, the gear shaft to withstand high pressure, high temperature, friction heat, in order to improve the service life of the melt pump on its lubrication, cooling is very necessary.

Melt pump gear shaft friction vice lubrication in a variety of ways: mainly wet lubrication, that is, between the pump body and the end cover with a herringbone flow groove, one end of the groove and the shaft gap, the other end and the low-pressure inlet, the melt in the formation of lubricant ester flow between the shaft gap and take away the high temperature of the friction. As the shaft gap is very small, the gap within the melt film shear rate is very high, heat generation, coupled with the shaft friction heating, will cause thermal degradation and mechanical shear degradation of the melt film of the material, the greater the impact on the product performance, but because of this lubrication cycle is not easy to detect inside the pump body, is often overlooked, and at the same time this lubrication will also be friction generated by the metal particles into the melt to affect the quality of the product.

Another lubrication mode of melt pump is dry lubrication, this lubrication mode of gear shaft, hole clearance within the melt is not involved in the lubrication cycle, will not cause material degradation of the melt aging, there is no wear and tear of the metal particles into the melt, this melt pump should be the product in the high temperature, high pressure environment without media lubrication design difficulties, complex structure, high cost, fewer applicants.

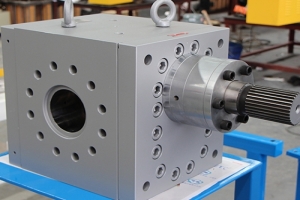

Heiko specializes in the manufacture of all types of melt pumps and screen changers.