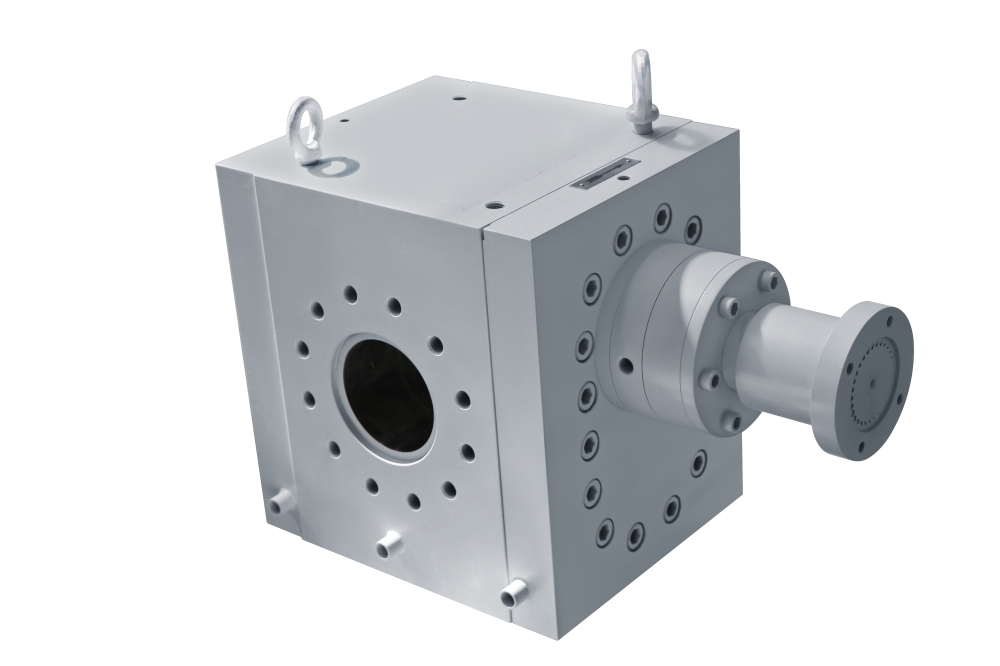

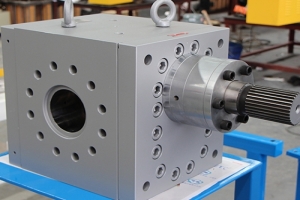

The main reasons for the melt booster pump gear jamming and end cap leakage

Zhengzhou Haike melt pump manufacturers based on years of experience summary analysis, that there are several reasons for the melt booster pump jamming and end cap leakage reasons:

1, due to the melt booster pump assembly precision is high, gear shaft and sliding bearing clearance in 0.2 mm, while the sliding bearing and gear shaft rely on the melt material self-lubrication, sliding bearing lubrication runner width of only 24 mm, lubrication flow is narrow, lubrication is poor, resulting in increased friction between the gear shaft and the sliding bearing is the main reason for jamming.

2、Sliding bearing material is tungsten carbide, the same material as the gear shaft, poor lubrication of the flow path is easy to cause the sliding bearing and gear shaft jamming hold phenomenon.

![]()

3, the melt booster pump pump body sealing surface can be clearly seen in 2 processing traces, proving that the pump body sealing surface is not a machining is completed, but by the lathe many times, resulting in the sealing end face unevenness, booster pump pump pressure up to 25 MPa, the sealing end face machining accuracy of the slightest deviation will cause the end of the end cover of the leakage.

Zhengzhou Haike melt pump manufacturers after analysis, for the melt booster pump frequent card stop the root cause is, melt gear pump sliding bearing lubrication channel is too small, can not guarantee the sliding bearing and spindle lubrication. Sliding bearing and spindle material is the same as the cemented carbide, poor lubrication is easy to cause the phenomenon of blocking the hold dead. Melt gear pump sealing end cover leakage melt is the root cause, sealing end cover and pump body sealing surface without sealing gaskets, the original manufacturer designed for glossy sealing, but the pump end cover and the pump body machining accuracy can not be precision fit, there is a gap, resulting in the end of the end cover at the melt seepage over.

Heiko specializes in the manufacture of all types of melt pumps and screen changers.