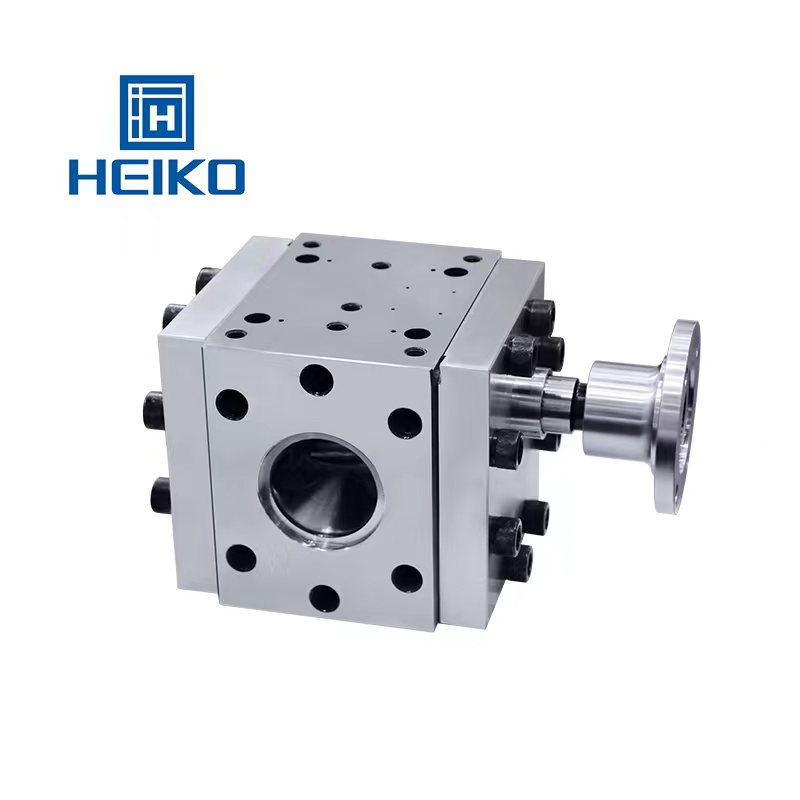

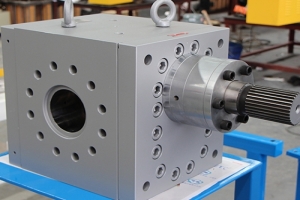

Melt gear pumps can be used in extrusion systems as metering pumps or extrusion pumps, and can be widely used in various extrusion industries, such as sheet, plate, pipe, film, pelletizing, drawing, cable, co-extrusion, mixing, precision extrusion and so on.

According to the different characteristics of materials, melt pumps used in extrusion systems can be divided into melt gear pumps for heat-sensitive materials, special gear pumps for rubber and elastomers, and economical melt pumps.

![]()

The main features and technical advantages of melt gear pumps for heat-sensitive materials are:

1、Optimized melt flow channel design: clear the dead space in the flow channel, reduce the polymer residue to a lower level, and improve the quality of the products;.

2、Optional built-in runner: suitable for runner cooling to adapt to more accurate and rapid temperature control system, can also be used for thermal fluid heating;.

3、Improved gear parameter design: more accurate rotary displacement design, so that the output pressure is more stable, suitable for precision extrusion conditions.

4、Applicable to a wide range of viscosity: the use of different sealing methods, can be applied from low viscosity to very high viscosity working conditions.

5、A variety of installation methods: to meet the different needs of users.

6、High precision manufacturing and heat treatment: more precise and durable.

Heiko specializes in the manufacture of all types of melt pumps and screen changers.