First, the advantages of hydraulic screen changer technology

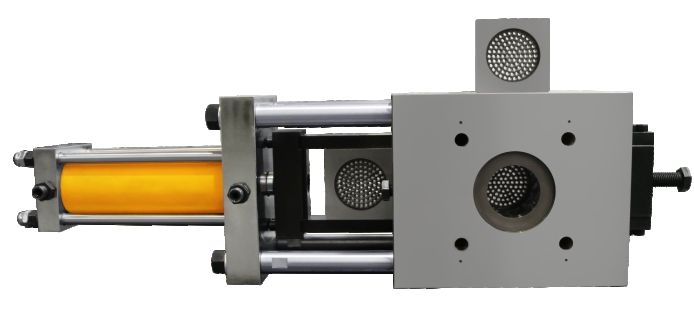

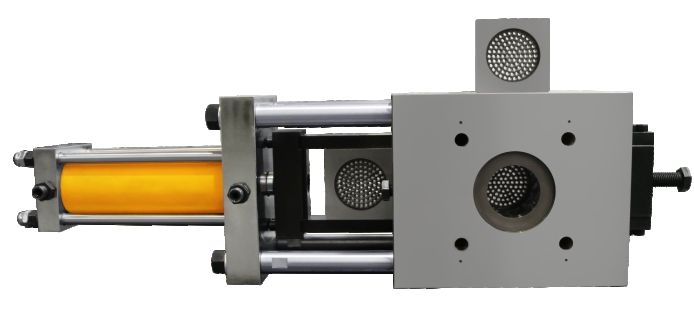

1. High-efficiency filtration: the hydraulic screen changer technology uses porous filter mesh, which can effectively intercept the impurities in the polymer solution and improve the filtration efficiency. At the same time, through the optimisation of the filter structure and material, can further enhance the filtration effect.

2. High degree of automation: hydraulic screen changer technology adopts automatic control system, which can achieve continuous and stable filtration operation. This not only reduces the tediousness and errors of manual operation, but also helps to improve production efficiency.

3. Extend the life of the filter screen: the filter screen of the hydraulic screen changer technology is made of high-quality materials with high corrosion and abrasion resistance. In addition, by regularly cleaning and replacing the screen, you can extend its service life and reduce maintenance costs.

4. Wide range of application: the hydraulic screen changer technology is applicable to the filtration of different types and concentrations of polymer solutions, and is highly versatile. In addition, the technology can be customised to meet the requirements of different production processes.

Second. Challenges of hydraulic screen changer technology

1. Technology R&D and innovation: In order to meet the ever-changing market demand and technological development, it is necessary to continuously strengthen the R&D and innovation of hydraulic screen changer technology. This involves research and application of new materials, new processes, intelligent control, etc., in order to improve filtration effect, reduce costs, enhance automation level and other aspects of continuous improvement.

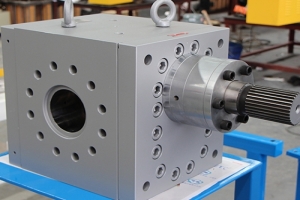

2. Equipment cost and maintenance: The equipment cost of hydraulic screen changer technology is relatively high, which may constitute a certain economic pressure for some SMEs. In addition, the routine maintenance and repair of the equipment also need to invest a certain amount of human, material and financial resources to ensure the normal operation of the equipment and extend the service life.

3. Operating skills and training: The operation of hydraulic screen changer technology requires certain professional skills and knowledge. In order to ensure the stable operation and production safety of the equipment, it is necessary to provide professional training and technical guidance to the operators to improve their operating level and ability to cope with emergencies.

4. Environmental protection and sustainable development: In the polymer filtration process, hydraulic screen changer technology needs to pay attention to environmental protection and sustainable development issues. Reasonable selection of environmentally friendly materials, reduce energy consumption, reduce waste emissions and other aspects are important issues facing this technology. At the same time, environmentally friendly technologies and solutions should be actively explored to achieve the harmonious unity of economic and environmental benefits.

Heiko specializes in the manufacture of all types of melt pumps and screen changers.