DETAILS

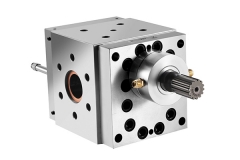

MP-H series high temperature and high pressure melt pumps are suitable for engineering plastics, blown film and other processes.

It can be applied to high temperature (≤510°C), high pressure (≤70MPa), high viscosity (≤20,000Pa·s);

The optimized design of the inlet and outlet avoids the dead angle in the runner to the greatest extent, reduces the material residue, and improved gear parameter design can withstand ultra-high pressures and greater differential pressure.

The use of special materials, high temperature resistance, long service life.

High-precision mechanical seals are used.

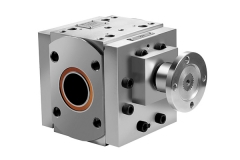

According to the customer's different site conditions, we can provide suitable installation methods, which is more flexible and practical.

H series melt pump can be installed in a variety of ways. The input shaft of the pump can be arranged horizontally or vertically (up and down), and the drive system generally includes motor, reducer, universal coupling, pump connector, reducer connector, etc.

The complete set of equipment includes melt pumps, inlet and outlet connectors, drive systems, control systems, etc. Customers can choose according to the specific situation