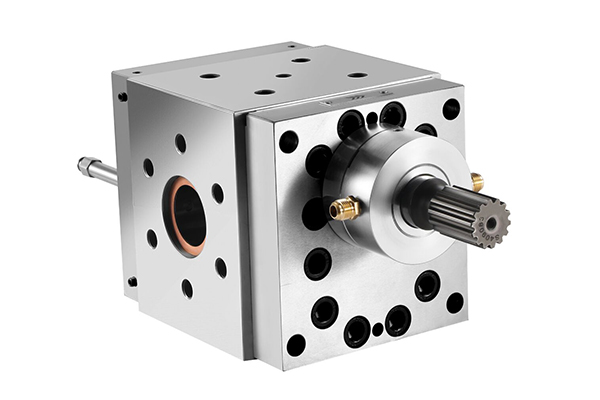

The M non-pulsation series is a universal melt pump for extrusion systems. It is mainly used for pressurization and stable flow transportation of extruders or medium and high viscosity polymers, such as sheets, plates, pipes, films, cables, co-extrusion, compounding, precision extrusion and other industries. It can also be installed in the melt pipeline and used as a booster pump; the heating method is mainly electric heating, which is suitable for PS, PP, PET, PA, ABS, PE-LLD and other processes.

The main features of the M series melt gear pumps:

It can be applied to high temperature (≤350C), high pressure (≤35MPa), high viscosity (≤20,000Pa·s);

Optimized runner design avoids dead angles in the runner, reduces material residue, and improves product quality.

The improved gear parameter design makes the output pressure more stable and the pulsation rate lower, which is suitable for precision extrusion.

It is made of high-temperature alloy steel, which has good wear resistance and long life.

Different sealing methods are used to adapt to a wide range of viscosities.

According to the customers’different site conditions, we can provide suitable installation methods, which is more flexible and practical

MP-M melt pump with drive system, equipped with explosion-proof heating hoses.