The plastic manufacturing industry is buzzing with excitement as a new revolutionary glue extrusion screen changer has hit the market. This state-of-the-art equipment is designed to significantly enhance the production efficiency and quality of glue and adhesive materials.

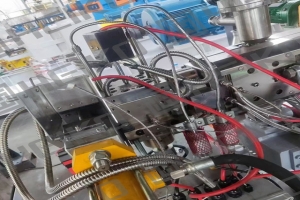

The glue extrusion screen changer is an advanced piece of machinery that is specifically engineered for use in plastic extrusion systems. Unlike traditional screen changers, this new model offers continuous and uninterrupted filtration of impurities during the extrusion process. This feature is particularly crucial in the production of glue and adhesive materials, where any disruption can lead to significant losses in productivity and quality.

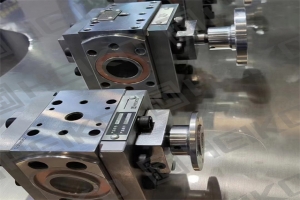

The screen changer is equipped with high-precision filter elements that ensure superior filter quality and increase the effective filtering area, thereby doubling the amount of filtering and guaranteeing high output. The use of oval hole screens further enhances the filtering efficiency, ensuring that only the purest materials are used in the production process.

One of the key highlights of this screen changer is its ability to operate continuously without the need for manual intervention. This not only minimizes personnel costs but also ensures a seamless production process, allowing manufacturers to achieve round-the-clock production capabilities. The device is also designed with high wear resistance and can handle high-voltage applications, making it suitable for use in a wide range of industrial sectors.

In addition to its technical advancements, the glue extrusion screen changer is also environmentally friendly. By enabling the reuse of plastic materials that would otherwise be disposed of, the device contributes to environmental sustainability and reduces waste. This is particularly important in today's world, where the need for eco-friendly solutions is becoming increasingly urgent.

The launch of the glue extrusion screen changer has been warmly welcomed by manufacturers in the plastic industry. Many have already started incorporating the device into their production processes, reporting significant improvements in productivity and quality. With its ability to handle high-volume production and ensure continuous filtration, the screen changer is poised to become a staple in the manufacturing of glue and adhesive materials.

In conclusion, the introduction of the glue extrusion screen changer represents a significant leap forward in the plastic manufacturing industry. Its innovative features, continuous filtration capabilities, and environmental sustainability make it a game-changer in the market. As manufacturers continue to adopt this technology, it is expected to revolutionize the production of glue and adhesive materials, driving the industry towards greater efficiency and quality.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447