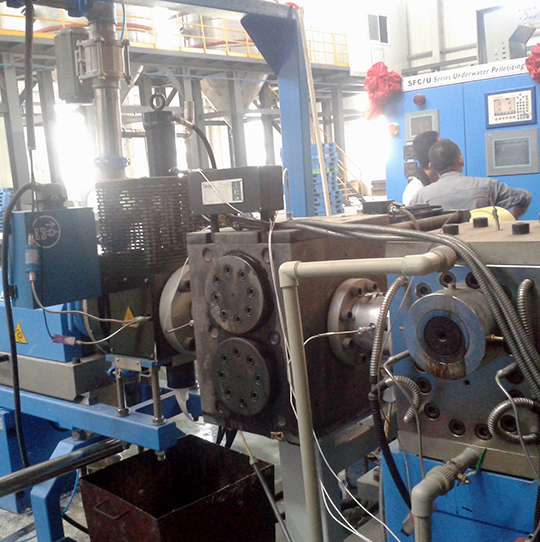

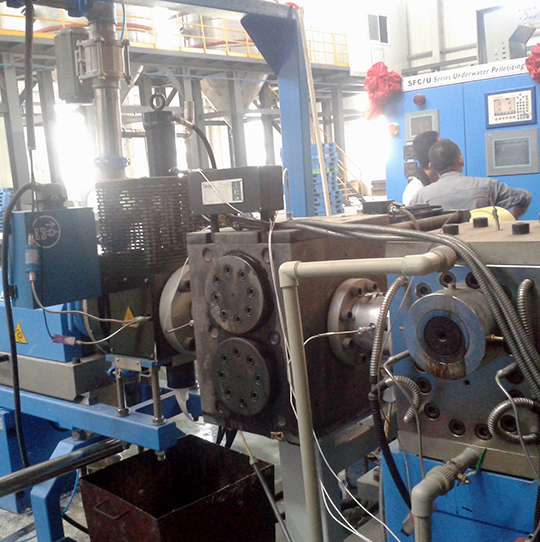

The plastic film extruder industry has witnessed a significant breakthrough with the introduction of an innovative screen changer technology that promises to revolutionize production efficiency and product quality. This advanced screen changer is designed to seamlessly filter impurities from the molten plastic resin during the extrusion process, ensuring a smoother and more consistent film output.

The traditional screen changers used in plastic film extrusion have long been prone to inefficiencies, such as frequent downtime for manual screen replacements and potential quality issues due to imperfect filtration. However, the newly developed screen changer addresses these challenges head-on by incorporating automated mechanisms and advanced materials.

"The new screen changer is a game-changer for our industry," said Mr. Zhang, a senior engineer at a leading plastic film extruder manufacturer. "Its automated system minimizes downtime, allowing for continuous production with minimal interruptions. Moreover, the high-precision filtration capabilities ensure that the final product meets the highest quality standards."

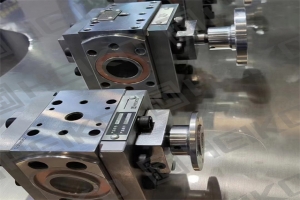

One of the key innovations of this screen changer is its ability to perform screen changes without stopping the extruder. This is achieved through a complex yet reliable mechanism that allows for the insertion of a new screen while the old one is still in use, ensuring a seamless transition. This not only boosts production efficiency but also reduces waste and labor costs.

Another notable feature of the new screen changer is its durability. Made from high-quality materials, it is designed to withstand the high temperatures and pressures encountered during the extrusion process. This extended lifespan further contributes to reducing maintenance costs and enhancing overall equipment effectiveness.

The introduction of this innovative screen changer comes at an opportune time, as the demand for high-quality plastic films continues to grow across various industries, including packaging, agriculture, and construction. With its ability to improve production efficiency and product quality, the new screen changer is expected to become a staple in plastic film extruder machinery.

As the plastic film extruder industry embraces this technological advancement, it looks forward to a future of increased productivity, reduced costs, and enhanced competitiveness in the global market. With the Chinese New Year of the Snake just around the corner, many manufacturers are hopeful that this innovative screen changer will bring them good fortune and success in the coming year.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447