The Challenge of Plastic Granulation

Plastic granulation is a critical step in the recycling process, where plastic waste is melted, filtered, and reshaped into small pellets for reuse in manufacturing. One of the most persistent challenges in this process has been the filtration of contaminants from molten plastic. Traditional screen changers, which are used to filter out impurities, often require frequent manual intervention, leading to production delays, increased labor costs, and inconsistent product quality.

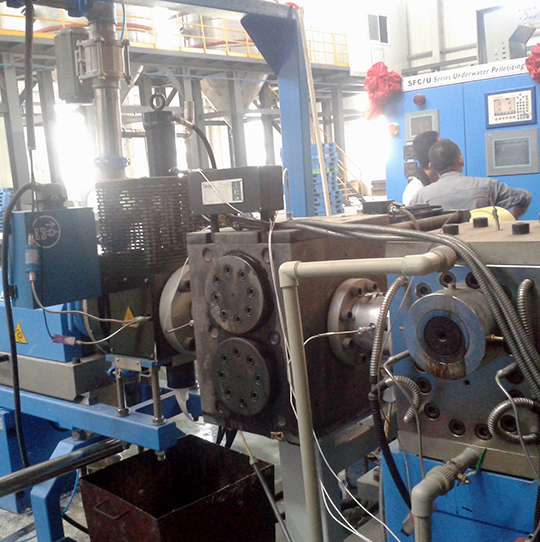

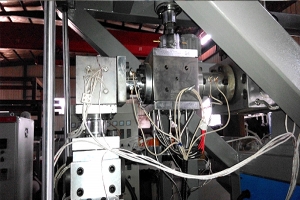

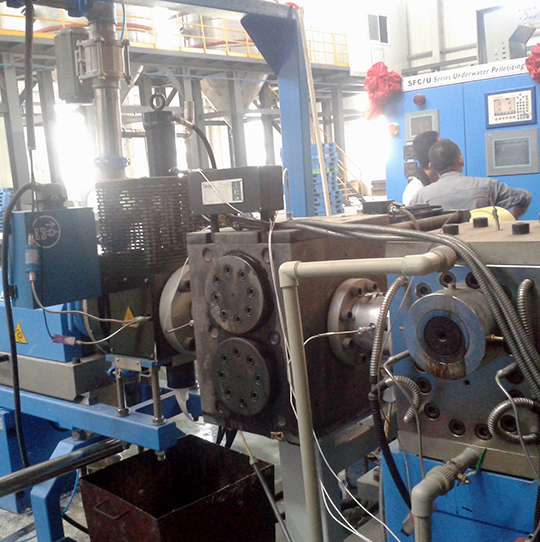

Enter the Hydraulic Screen Changer

The newly developed hydraulic screen changer addresses these issues head-on. Engineered with advanced automation and precision hydraulics, the device allows for seamless, on-the-fly screen changes without interrupting the production process. This innovation significantly reduces downtime, ensuring a continuous flow of high-quality granulated plastic.

Key features of the hydraulic screen changer include:

Automated Operation: The system uses sensors and programmable logic controllers (PLCs) to detect screen clogging and automatically initiate a screen change, minimizing human intervention.

Enhanced Durability: Built with high-grade materials, the screen changer is designed to withstand the harsh conditions of plastic granulation, including high temperatures and pressures.

Improved Filtration Efficiency: The device offers finer filtration capabilities, ensuring that even the smallest contaminants are removed from the molten plastic.

Cost Savings: By reducing downtime and labor requirements, the hydraulic screen changer lowers operational costs, making it an attractive investment for recycling facilities.

Industry Impact

The introduction of this technology comes at a crucial time, as global demand for recycled plastics continues to rise. Governments and corporations alike are under increasing pressure to meet sustainability targets and reduce plastic waste. The hydraulic screen changer not only supports these goals but also enhances the economic viability of plastic recycling by streamlining operations and improving output quality.

"Plastic recycling is no longer just an environmental imperative—it's a business opportunity," said Dr. Emily Carter, a materials scientist and sustainability expert. "Innovations like the hydraulic screen changer are game-changers, making recycling processes more efficient and cost-effective while delivering higher-quality materials."

Adoption and Future Prospects

Early adopters of the technology have reported significant improvements in their operations. A major European recycling facility, which piloted the hydraulic screen changer earlier this year, saw a 30% reduction in downtime and a 15% increase in production output. Similar success stories are emerging from manufacturers in Asia and North America, signaling widespread potential for the technology.

Looking ahead, industry experts predict that the hydraulic screen changer will become a standard feature in plastic granulation systems worldwide. As the technology evolves, further advancements in automation and filtration precision are expected, paving the way for even greater efficiencies in the recycling process.

A Step Toward a Circular Economy

The development of the hydraulic screen changer underscores the importance of innovation in achieving a circular economy for plastics. By enabling more efficient and effective recycling, this technology not only reduces the environmental impact of plastic waste but also supports the creation of a sustainable, closed-loop system for plastic production and reuse.

As the world continues to grapple with the plastic pollution crisis, solutions like the hydraulic screen changer offer a glimmer of hope—a tangible step toward a cleaner, greener future.