In modern industrial production, the sheet extrusion pump, as a crucial fluid conveying equipment, is playing an increasingly important role. We delved into the working principle, advantages, and wide applications of sheet extrusion pumps in industrial production, revealing how this equipment has become an indispensable part of modern manufacturing.

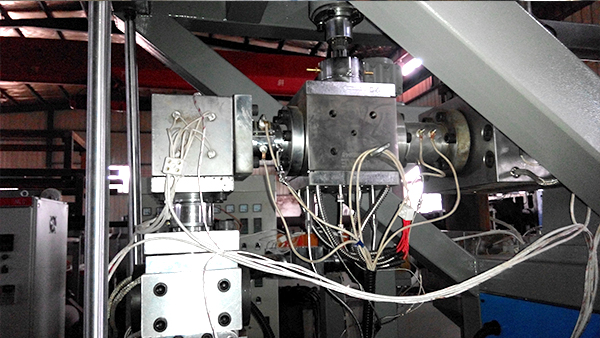

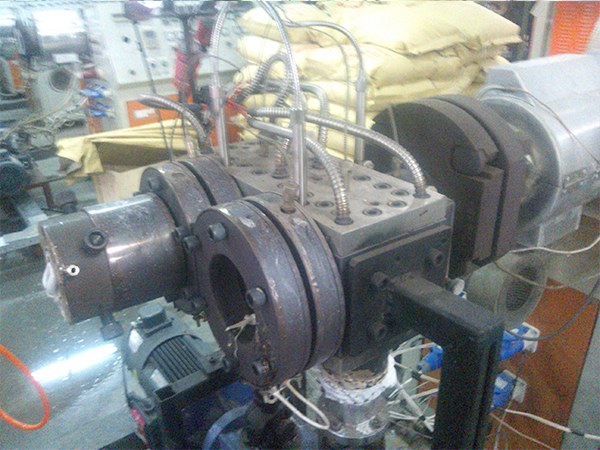

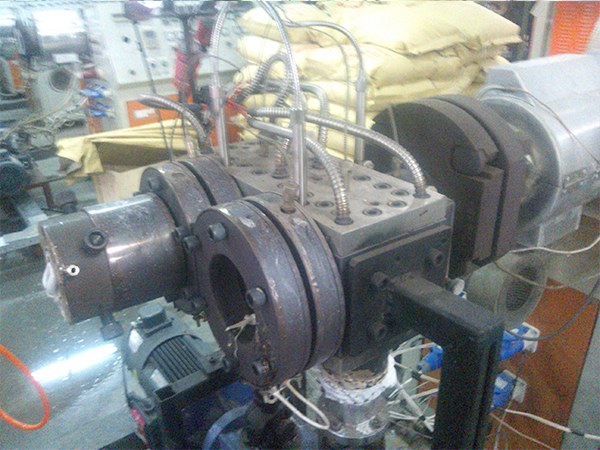

As its name implies, the sheet extrusion pump is primarily used in sheet extrusion lines, responsible for precisely controlling the flow rate and pressure of the melt. Its structure typically consists of precision components such as the pump casing, driving gear, driven gear, sliding bearings, front and rear end plates, and gland seals. The perfect coordination of these components ensures smooth flow of the melt within the pump, thereby guaranteeing the stability of the extrusion process and product quality.

In terms of its working principle, the sheet extrusion pump relies on the mutual engagement of the driving and driven gears to convey the melt through changes in working volume. As the gears rotate, the melt is introduced into the tooth spaces and is squeezed and propelled forward with the continued rotation of the gears, ultimately being conveyed to downstream equipment through the outlet pipeline. This process not only achieves precise conveyance of the melt but also ensures stability of the melt viscosity, avoiding issues such as clogging or poor pumping due to temperature changes.

In industrial production, the advantages of sheet extrusion pumps are evident. Firstly, it can precisely control the flow rate and pressure of the melt, which is crucial for improving the dimensional accuracy and surface quality of sheet products. Secondly, by adjusting the pump's rotational speed and gear clearance, the sheet extrusion pump can meet the production needs of different sheet products, demonstrating high flexibility and adaptability. Additionally, its ability to maintain melt viscosity stability ensures continuity and stability in the production process.

It is worth mentioning that sheet extrusion pumps have a wide range of applications across multiple industries. In the plastics processing industry, it is one of the core equipment in sheet and plate extrusion lines; in the rubber industry, it can be used to convey various rubber raw materials and semi-finished products; and in the chemical industry, it can be used to convey various high-viscosity, high-concentration chemical media. Furthermore, with the continuous advancement of technology, the applications of sheet extrusion pumps in industries such as food, pharmaceuticals, and renewable energy are constantly expanding.

However, despite its many advantages, there are still some issues to consider in practical applications of sheet extrusion pumps. For example, regular inspections and maintenance of pump components are necessary to ensure they are in good working condition; when conveying corrosive or high-temperature media, suitable pump body and sealing materials need to be selected; and during operation, strict adherence to operating procedures is required to avoid equipment damage or safety accidents caused by improper operation.

Looking ahead, with the continuous development of Industry 4.0 and smart manufacturing, sheet extrusion pumps will also evolve towards higher efficiency, intelligence, and environmental friendliness. By incorporating advanced technologies such as sensors, controllers, and actuators, functions such as remote monitoring, fault diagnosis, and preventive maintenance of the equipment can be realized, further improving operational efficiency and reliability, while reducing energy consumption and environmental pollution. Meanwhile, the application of new materials will further enhance the pump's corrosion resistance and wear resistance, extending its service life and expanding its application fields.

In summary, as a precision power source in modern industrial production, the sheet extrusion pump is contributing significantly to the transformation and upgrading, as well as high-quality development of the manufacturing industry with its unique working principle and wide range of applications. We have reason to believe that in the future, it will continue to play an even greater role, creating more miracles for human industrial production.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447