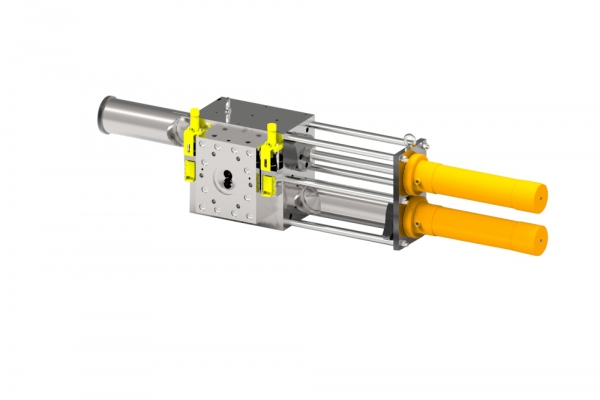

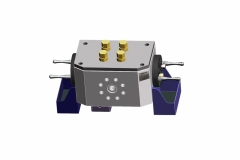

This series of screen changing filters is designed with a four-channel four-screen structure, and the four screens work at the same time, without interrupting the material flow and the product, so as to achieve non-stop screen change. The exhaust system is designed to fully exclude the gas contained in the material and the perforated plate to be replaced, prevent the formation of gas in the product during the screen changing process, and improve the quality of the product.

The backwashing function is designed to realize the online backwashing filter, and the filter screen can be reused more than 200 times.

The four-channel design maximizes the filtration area and meets the requirements for higher throughput and higher quality.

It is used in the manufacture of chemical fiber, blown film, flat film, cast film, pipe, plate, wire rod and fiber, pelletizing, recycling and granulation, etc.

Large filtration area, suitable for extrusion production of different materials and products.

It has good sealing characteristics, rigid sealing, and long service life.

It is especially suitable for the processing of recycled plastics and the addition and utilization of large proportion of recycled plastics.

It has the function of automatic net washing to avoid frequent screen changing.

Increase production and save energy and save production costs.

It has a safety shield design.

The structure design is reasonable, the operation is convenient, and the effect is excellent.