The application scope of polymer melt pumps in plastic film extrusion machines is quite extensive, mainly manifested in the following aspects:

I. Plastic Film Manufacturing

In the production process of PVC films, the melt pump plays a crucial role. It can precisely control the flow rate and pressure of the melt, ensuring that the film has a more uniform thickness and a smoother, flatter surface. This characteristic helps improve the quality and performance of the film, thereby meeting the requirements of different application fields for films. For example, in packaging, agriculture, construction, and other industries, there are strict requirements for the tensile strength, transparency, and aging resistance of films. The application of melt pumps can significantly enhance these performance indicators.

II. Plastic Pipe Production

Although the question mainly inquiries about the application of melt pumps in plastic film extrusion machines, it is worth mentioning that melt pumps also excel in the extrusion process of PVC pipes. They can stabilize and pressurize the high-temperature, high-viscosity PVC melt extruded by the extruder and then stably deliver it to the extruder head, ensuring the dimensional accuracy and quality stability of the pipes. This characteristic is particularly important in water supply, drainage, gas, and other piping systems because the dimensional accuracy and quality stability of the pipes directly relate to the system's safety and service life.

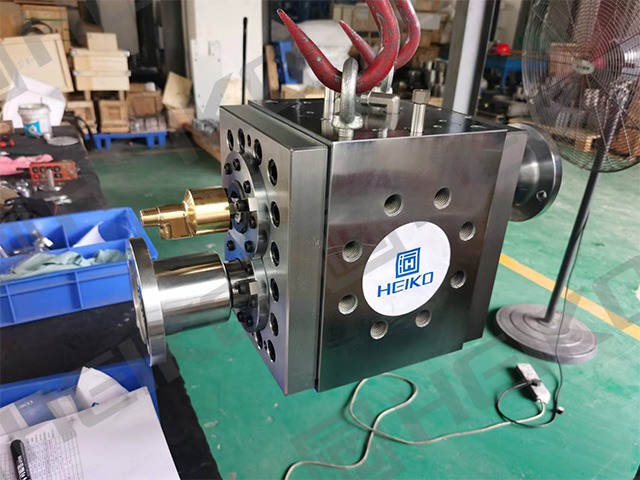

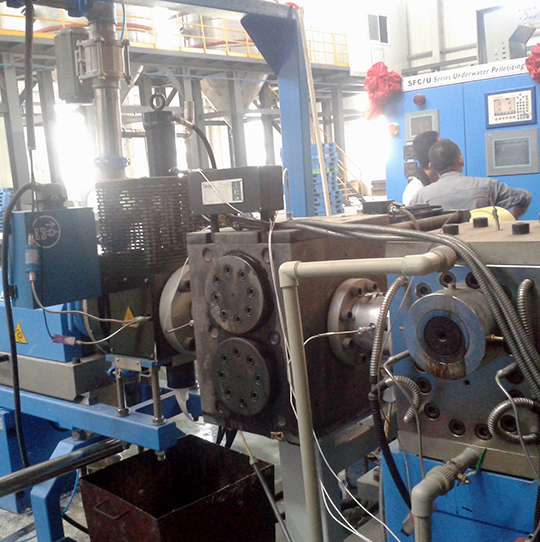

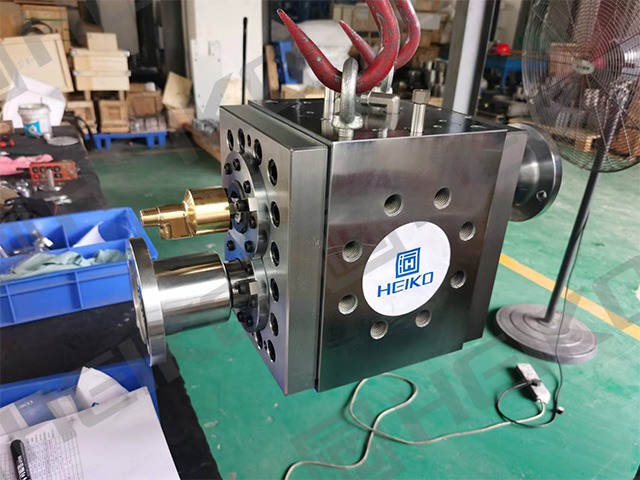

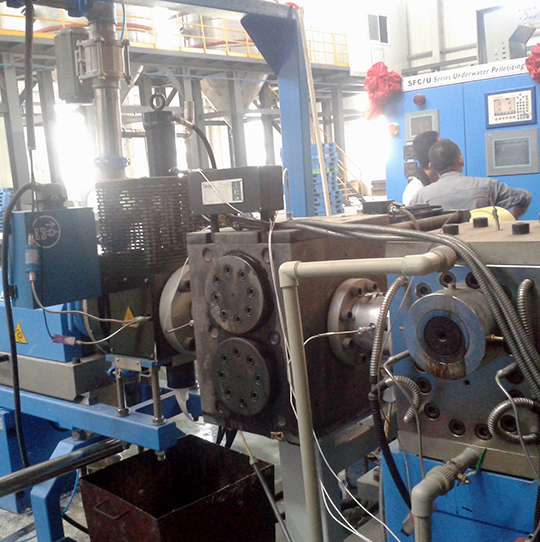

III. Plastic Granulation and Mixing

In the plastic granulation process, the melt pump can accurately meter and stably convey plastic materials that have undergone initial mixing and melting, making the granulation process more efficient and stable. The resulting plastic granules have a uniform quality, providing high-quality raw materials for subsequent plastic product processing. Additionally, in the plastic mixing process, the melt pump can also ensure the uniform mixing of various raw materials, improving mixing efficiency and quality.

IV. Other Plastic Processing Areas

Besides the aforementioned application fields, melt pumps are also widely used in the extrusion molding of plastic sheets and plates, ensuring stable melt supply and precise metering, which improves product dimensional accuracy and appearance quality. Furthermore, in plastic injection molding, blow molding, and other processes, melt pumps also play a significant role in achieving efficient and stable melt conveyance and control.

V. Chemical Fiber and Resin Industries

In the chemical fiber and resin industries, melt pumps also have extensive applications. They are typically installed at the bottom of reaction vessels as discharge pumps, suitable for the reactive conveyance of high-temperature, high-viscosity polymer melts that require high output pressure. This characteristic enables melt pumps to ensure stable material conveyance and efficient utilization in the production processes of chemical fibers and resins.

In summary, the application scope of melt pumps in plastic film extrusion machines is not limited to plastic film manufacturing but also extensively involves plastic pipe production, plastic granulation and mixing, other plastic processing areas, as well as the chemical fiber and resin industries. Their ability to precisely control melt flow rate and pressure, and their characteristics of improving product quality and production efficiency, make melt pumps play an irreplaceable role in these fields.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447